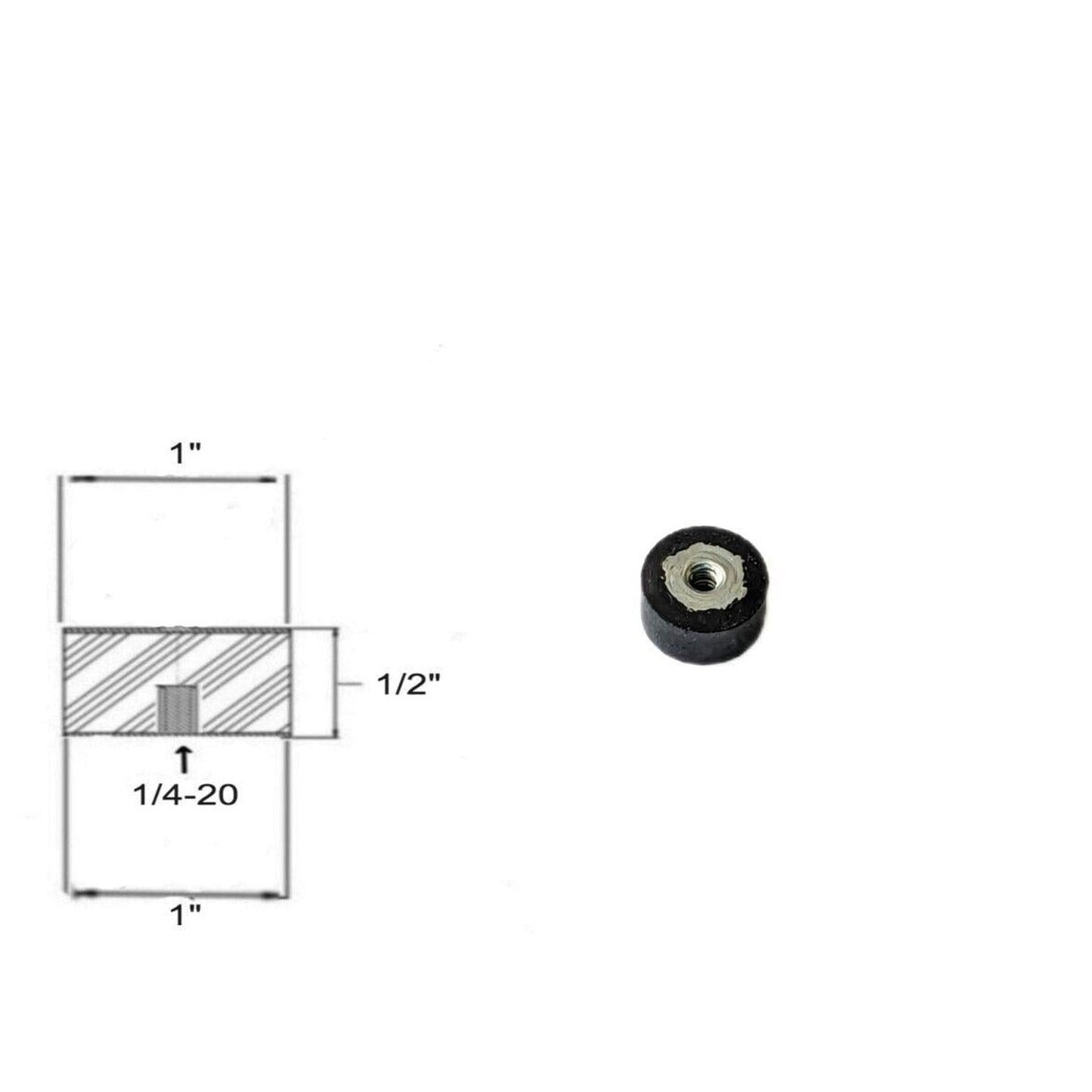

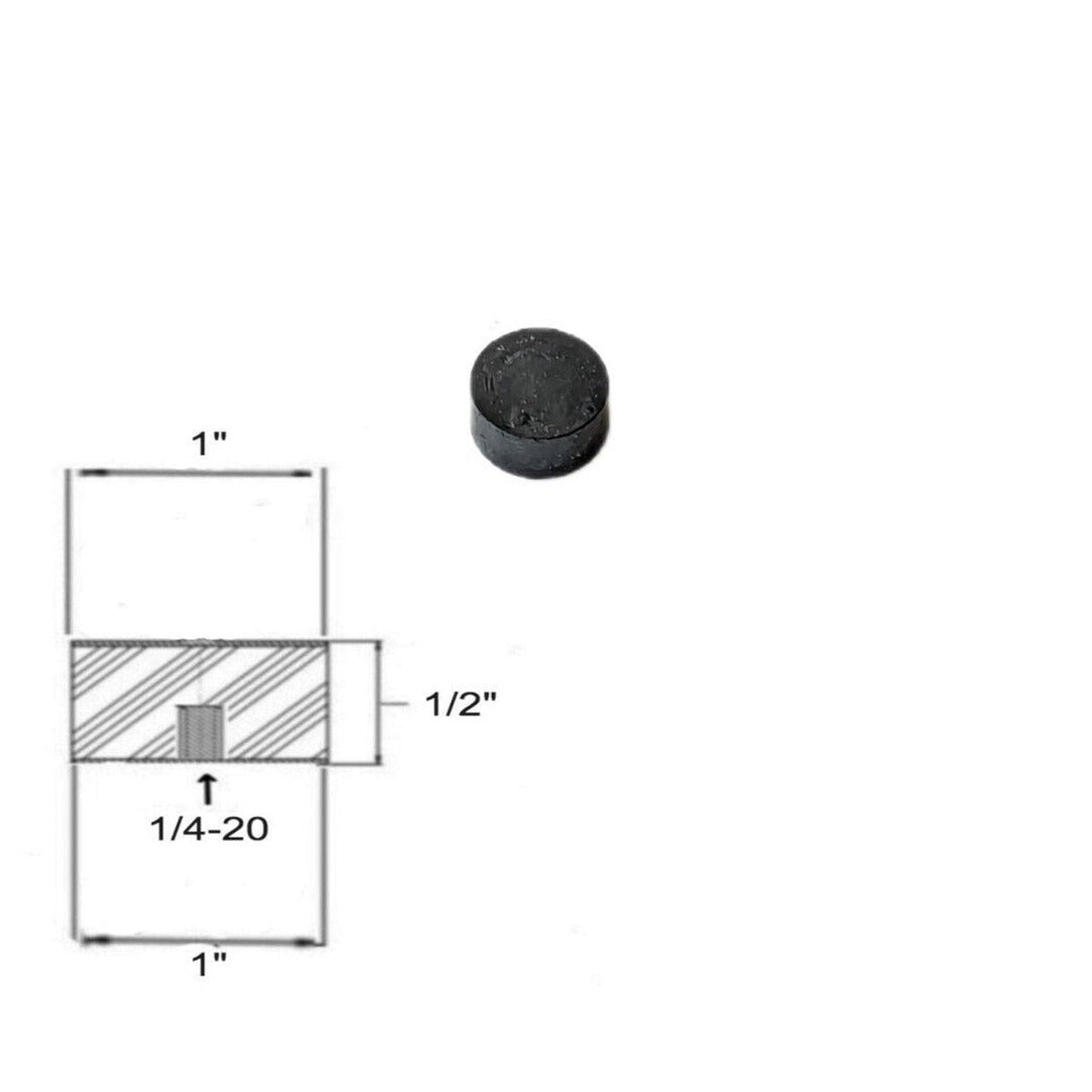

VBM1121420FB

Rubber Vibration Isolator Mount (1" Dia x 1/2'' Thk) 1/4-20 female threaded

Rubber Vibration Isolator Mount (1" Dia x 1/2'' Thk) 1/4-20 female threaded

496 in stock

Couldn't load pickup availability

Want it shipped out today? Order by 2pm ET

Shop safely

Secure your shopping experience with various safe and trusted payment methods.

- These mounts measure 1/2" in thickness (rubber height) and 1" in diameter (rubber diameter)

- Threaded hole is 1/4-20 threads.

- Material Composition: Crafted from industrial-grade, high-resilience rubber.

Performance and Efficiency

- Vibration Dampening: Excellently reduces both vibrational impact and noise levels.

- Load Capacity: Optimally designed to handle specified load ranges while maintaining performance.

- Durability: Resistant to environmental factors like moisture and chemicals.

Features and Benefits

- Superior Material Choice: Utilizes premium rubber, ensuring lasting resilience under various conditions.

- Cutting-Edge Design: Incorporates advanced vibration dampening technology for optimal performance.

- Broad Application Spectrum: Adaptable to a myriad of settings, from delicate medical equipment to robust industrial machinery.

- Noise Suppression Excellence: Significantly reduces acoustic vibrations, contributing to a quieter and more stable environment.

Installation Guide

Step-by-Step Mounting Procedure

- Surface Preparation: Start by cleaning the installation surface to ensure it's free of debris and moisture.

- Mount Positioning: Carefully position the vibration isolator mount at the designated installation point.

- Securing the Mount: Utilize an appropriate tool (such as a socket wrench) to tighten the stud into place, ensuring a firm and secure fit.

- Alignment Verification: Double-check that the mount is aligned correctly for maximum efficiency.

- Load Testing: Gently apply a load to test the stability and effectiveness of the installation.

- Regular Inspection: Periodically check the mount for signs of wear or loosening.

Application Chart

How they can be used

| Application | Examples |

|---|---|

| Industrial Machinery | Absorbing operational vibrations in heavy machinery. |

| HVAC Systems | Stabilizing HVAC units against structural vibrations. |

| Automotive Engines | Reducing engine vibration for smoother vehicle operation. |

| Aerospace Equipment | Essential for vibration control in sensitive aerospace components. |

| Electrical Generators | Minimizing noise and vibration in power generation units. |

| Marine Engines | Critical in dampening vibrations in maritime environments. |

| Laboratory Equipment | Vital for precision instruments' stability in research settings. |

| Construction Machinery | Enhancing the longevity of construction equipment by reducing vibrational stress. |

| Computing Equipment | Protecting technological infrastructure from harmful vibrations. |

| Audio Equipment | Isolating studio and stage equipment from external vibration. |

| Railway Cars | Improving passenger comfort in rail transport systems. |

| Compressors | Essential in noise and vibration reduction for compressor units. |

| Printing Presses | Stabilizing printing machinery for high-quality output. |

| Medical Devices | Ensuring operational stability of delicate medical apparatus. |

| Fitness Equipment | Reducing structural impact in gym machinery. |

| Factory Conveyors | Maintaining the smooth operation of conveyor belt systems. |

| Camera Stabilization | Key in reducing vibration in professional filming and photography. |

| Wind Turbines | Enhancing efficiency and reducing wear in renewable energy installations. |

| Pump Systems | Crucial for maintaining operational stability in various pump systems. |

| Ventilation Systems | Decreasing vibrational impact in large-scale ventilation setups. |

| Home Appliances | Essential in reducing operational noise in household appliances. |

| Seismic Protection | Providing structural damping in earthquake-prone areas. |

| Musical Instruments | Minimizing feedback and maintaining sound quality in audio systems. |

| Packaging Machinery | Stabilizing bottling and packaging processes in industrial settings. |

| Robotics and Automation | Ensuring precision and reducing wear in automated systems. |

| Garage Door Openers | Reducing noise and improving the longevity of garage door mechanisms. |

| Workshop Power Tools | Essential in maintaining precision in workshop tools. |

| Home Theater Systems | Enhancing audio quality by minimizing vibrations. |

| Air Conditioning Units | Key in reducing noise levels in both residential and commercial AC units. |

| Vibration Isolation Tables | Providing stability in sensitive laboratory and workshop tasks. |

| Engine Test Stands | Vital for accurate testing and analysis in automotive development. |

| Industrial Mixers | Reducing vibrational impact in large-scale industrial mixers. |

| Photocopier and Office Equipment | Maintaining operational efficiency in office machinery. |

| Vibratory Feeders | Controlling material flow and reducing mechanical stress. |

| Elevators and Lifts | Enhancing ride comfort and equipment longevity in vertical transportation. |

In-Depth FAQs

Answering Key Questions

Q: How does this product adapt to different environments?

A: Its robust design and material choice allow it to function effectively across diverse settings, from delicate indoor equipment to harsh outdoor machinery.

Q: What maintenance is required for these mounts?

A: Regular inspections for wear and proper alignment ensure long-term functionality and effectiveness.

Q: What materials are these vibration isolator mounts made of?

A: They are primarily made from high-grade rubber, known for its durability and excellent vibration dampening properties. The metal components are typically steel or other robust metals for added strength and stability.

Q: Can these mounts be used in outdoor environments?

A: Yes, these mounts are designed to withstand various environmental conditions, including outdoor settings. The rubber is resistant to weather elements, and the metal parts are often treated to prevent rust and corrosion.

Q: How do I choose the right size mount for my application?

A: The selection depends on the weight and vibration frequency of the equipment. It's crucial to consider both the load capacity and the size of the mount to ensure optimal vibration isolation. Consulting with a specialist or referring to technical specifications is advisable for precise selection.

Q: Are these mounts easy to install?

A: Yes, they are designed for ease of installation. Basic tools like a wrench or screwdriver are typically sufficient. The step-by-step guide provided with the product outlines the installation process clearly.

Q: How effective are these mounts in reducing noise?

A: Along with vibration reduction, these mounts are highly effective in noise dampening. By minimizing the vibrations, they inherently reduce the noise produced by machinery and equipment.

Q: What maintenance do these vibration isolator mounts require?

A: Maintenance is minimal. It involves regular inspection for signs of wear and tear, ensuring the mount is still securely attached and checking for any degradation in the rubber material.

Q: Are these mounts suitable for sensitive equipment like laboratory instruments?

A: Yes, they are. These mounts provide the stability and vibration control needed for sensitive and precise instruments, making them suitable for laboratory environments.

Q: How long do these mounts typically last?

A: The lifespan varies based on usage intensity, environmental conditions, and the specific application. However, they are built for durability and long-term use under standard operating conditions.

Q: Can these mounts be customized for specific applications?

A: In many cases, customization options are available. We often offer variations in size, load capacity, and material composition to suit specific requirements.

Shopping Safely

At our Shopify store, we prioritize your safety and security. Here's how we ensure a secure shopping experience:

1. Secure Transactions: We use advanced encryption to protect your personal and payment information, ensuring it is safely transmitted and safeguarded.

2. Trusted Payment Gateways: Our store integrates with trusted payment gateways, ensuring your transactions are processed securely and efficiently.

3. Data Privacy: Your privacy is our top priority. We follow strict data protection policies to keep your personal information confidential and secure.

4. Secure Platform: Shopify provides robust security features and continuous monitoring against vulnerabilities, ensuring a safe shopping environment.

5. Verified Merchants: We are a verified merchant on Shopify, committed to providing authentic and high-quality products.

6. Transparent Policies: Our clear return, refund, and shipping policies provide peace of mind, knowing we stand behind our products.

7. Customer Support: Our dedicated customer support team is ready to assist with any concerns or questions you may have.

Shop confidently at our Shopify store, where your safety and satisfaction are our top priorities.

$2.25 USD

-

WELL TRUSTEDOver 100k customers

-

SUPER FASTWith Express delivery

-

EXPERT HELPSeven days a week

-

BEST PRICESUnbeatable value